In the world of industrial processes and machinery, maintaining the stability and efficiency of systems is paramount. One critical component that plays a vital role in this regard is the anti-surge valve. This article explores what an anti-surge valve is and delves into its functions, shedding light on its significance in various industries.

Understanding Anti-Surge Valves

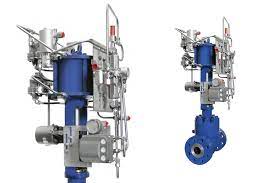

An anti-surge valve, also known as an antisurge control valve or compressor recycle valve, is a specialized device used primarily in the oil and gas industry, as well as in various other sectors that rely on compressors and turbines. Its main purpose is to prevent surging in these machines, which can be detrimental to their operation.

- Preventing Surging: One of the primary functions of an anti-surge valve is to prevent surging in compressors and turbines. Surging occurs when the flow of gas or fluid through these machines becomes unstable, leading to fluctuations in pressure and flow rates. Surging can result in severe damage to the equipment and reduce overall efficiency.

- Maintaining Stability: Anti-surge valves help maintain stability in the system by regulating the flow of gas or fluid. They do this by opening and closing in response to changing conditions, ensuring that the compressor or turbine operates within safe parameters.

- Protecting Equipment: These valves act as a protective mechanism for expensive and critical equipment. By preventing surging, they reduce wear and tear on the machinery, extend their lifespan, and minimize the need for costly maintenance and repairs.

- Enhancing Efficiency: Anti-surge valves also contribute to improving the efficiency of compressors and turbines. By optimizing the flow and pressure conditions, these valves enable the equipment to operate at its peak performance, resulting in energy savings and reduced operating costs.

- Safety Measures: In addition to their role in equipment protection, anti-surge valves play a crucial role in ensuring the safety of the entire system. They prevent potentially hazardous situations that can arise from surging, such as equipment failure, leaks, or even explosions.

Anti-Surge Valves in Various Industries

Anti-surge valves find applications in a wide range of industries beyond oil and gas:

- Chemical Industry: They are used to maintain stable operations in chemical processing plants, where compressors are integral to various processes.

- Power Generation: In power plants, especially those that rely on gas turbines, anti-surge valves help ensure consistent and efficient power production.

- Petrochemical Industry: These valves play a crucial role in preventing surging in petrochemical facilities, safeguarding equipment and personnel.

- Refineries: Anti-surge valves are essential components in refining operations, where they help control the flow of gases and maintain stability.

Conclusion

In conclusion, anti-surge valves are vital components in various industries, serving the critical function of preventing surging and ensuring the stability and efficiency of compressors and turbines. Their significance extends beyond equipment protection, encompassing safety, energy efficiency, and cost savings. Understanding the role of anti-surge valves is essential for anyone involved in industrial processes, as they are integral to the smooth and safe operation of many systems.

FAQs About Anti-Surge Valves

What is an anti-surge valve?

An anti-surge valve, also known as an antisurge control valve or compressor recycle valve, is a specialized device used primarily in industries like oil and gas, power generation, and petrochemicals. Its main function is to prevent surging in compressors and turbines.

What is surging, and why is it a concern in industrial processes?

Surging refers to an unstable flow of gas or fluid in compressors and turbines, leading to fluctuations in pressure and flow rates. It is a concern because it can damage equipment, reduce efficiency, and pose safety risks.

How do anti-surge valves work?

Anti-surge valves regulate the flow of gas or fluid through a compressor or turbine. They open and close in response to changing conditions to ensure the system operates within safe parameters and prevents surging.

What are the primary functions of anti-surge valves?

The primary functions of anti-surge valves include preventing surging, maintaining system stability, protecting equipment from damage, enhancing efficiency, and ensuring the safety of the entire system.

In which industries are anti-surge valves commonly used?

Anti-surge valves are commonly used in industries such as oil and gas, chemical processing, power generation, petrochemicals, and refineries. They are essential in any industry that relies on compressors and turbines.

How do anti-surge valves contribute to energy efficiency?

By preventing surging and optimizing the flow and pressure conditions, anti-surge valves enable compressors and turbines to operate at their peak performance. This results in energy savings and reduced operating costs.

Are there different types of anti-surge valves?

Yes, there are different types of anti-surge valves, including pneumatic and electronic control valves. The choice of valve type depends on the specific application and control requirements.

What maintenance is required for anti-surge valves?

Regular maintenance is essential to ensure the proper functioning of anti-surge valves. This may include cleaning, lubrication, inspection, and calibration, depending on the manufacturer’s recommendations and industry standards.

Can anti-surge valves be used in retrofits or upgrades of existing systems?

Yes, anti-surge valves can be retrofitted into existing systems or used as part of upgrades to enhance the stability and efficiency of older equipment.

How can I determine if my system needs an anti-surge valve?

If your industrial process involves compressors or turbines and experiences issues with surging, instability, or efficiency, it’s advisable to consult with a professional engineer or expert in control systems. They can assess your specific needs and recommend whether an anti-surge valve is necessary.