GE Gas turbines

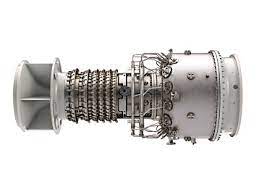

MS5001 Gas turbine

The MS5001 single shaft turbine is a compact heavy-duty prime mover with ISO rated power of 26.8 MW designed for long life and ease of operation and maintenance. The three main features of its simple design are: -17-stage, axial compressor-Combustion system with 10 chambers capable of burning a wide range of fuels including natural gas, light and heavy distillates, and crude and residual oil. A DLN System is also available.-Two-stage turbine with high energy stage design. The first-stage nozzles are cooled by the axial compressor discharge air.

The MS5001 Gas Turbine is the ideal solution for power generation where low maintenance, reliability and economy of fuel utilization are required. Low operating and investment costs make the MS5001 packaged power plant an economically attractive system for load generation. The MS5001 is also ideally suited for cogeneration achieving a very high fuel utilization index and considerable fuel savings. Typical applications are industrial plants for cogeneration of power and process steam or district heating systems.

MS5002 C-D Gas turbine

The MS5002 is a gas turbine specifically designed for mechanical drive applications such as gas boosting, gas injection/re-injection, oil & gas pipelines, LNG plants and gas storage. It has a broad operating speed range to meet the operating requirements of the most common driven equipment (centrifugal compressors and pumps) as well as the ability to burn a large variety of gaseous and liquid fuels. Presently two versions are available:

-MS5002C with ISO rated power of 28.34 MW

-MS5002D with ISO rated power of 32.58 MW

MS6001B

The MS6001 is a single-shaft, heavy-duty gas turbine. The high efficiency axial compressor has 17 stages. The combustor has ten combustion chambers with individual fuel nozzles. The machine has a three-stage impulse turbine with air-cooled buckets and stationary nozzles on the first two stages to achieve higher firing temperatures and consequently higher efficiency without compromising hot section component life.

PGT25 Aeroderivative Gas Turbines

The PGT25 gas turbine consists of an LM2500 GE aeroderivative gas generator coupled with a rugged, industrial power turbine designed by GE’s Oil & Gas business.

GAS GENERATOR

The LM2500 gas generator has already accumulated several million fired hours not only as an aircraft engine (TF39 and CF6-6 engines), but also in the industrial field in many mechanical drive applications (marine, onshore and offshore gas transmission) and for generator drive service. The LM2500 gas generator incorporates a 16-stage axial-flow compressor capable of reaching an 18:1 pressure ratio. Inlet guide vanes and adjustable stator vanes on the first six compressor stages provide for efficient operation over the entire operating range.

POWER TURBINE

The PGT25 power turbine components were designed taking into account many years of experience gained in the field by heavy duty gas turbines and axial/centrifugal compressors. The aerodynamic blading was designed with the main objective of obtaining very high efficiency at both design and reduced speeds. The 6500 RPM design speed means the turbine can have two stages with a moderate aerodynamic load and a high expansion efficiency. The two expansion stages are of the high energy, three-dimensional design type.

Siemens Gas Turbines

SGT-100:

SGT-100 is a 5.4 MW industrial gas turbine for electrical power generation and mechanical drive applications. features a 10-stage axial flow transonic compressor incorporating the latest aerodynamic technologies.

SGT-200:

SGT-200 is an axial-flow industrial gas turbine in the 6-7MW power band.

Since its introduction in 1981, the SGT-200 (formerly known as the Ruston Tornado) was revolutionary in design, meeting the advancing requirements of both power generation and oil & gas sector.

SGT-300:

SGT-300 is a twin-shaft engine for mechanical drive and power generation with the maximum mechanical drive of 9.2 MW. It has a compact arrangement, on-site maintainability and inherent reliability.

SGT-400:

The SGT-400 is a simple, robust twin-shaft gas turbine, suitable for both power generation and mechanical drive applications. The product services the 10 – 15 MW power band and can be used in all climates, onshore and offshore.

SGT-600:

The SGT-600 has 24.5 MW power generation and features a 10-stage flow transonic compressor with variable guide vanes for robust operability and optimized performance over a wide range of operating conditions.

V94.2 (SGT5-2000E)

Proven E-class turbine with outstanding fuel flexibility with 187 MW power for Simple cycle power generation. It is a proven, robust engine for the 50 Hz market, used in simple cycle or combined cycle processes, with or without combined heat and power.