Welcome to a comprehensive guide on “What Is Reaction Turbine? | Reaction Turbine | Working of Reaction Turbine | Parts of Reaction Turbine.” In this article, we will delve into the intricate world of reaction turbines, shedding light on their functionality, components, and the science behind their operation. If you’ve ever wondered how these turbines work or what makes them an integral part of various industries, you’re in the right place. So, let’s dive right in!

What Is Reaction Turbine?

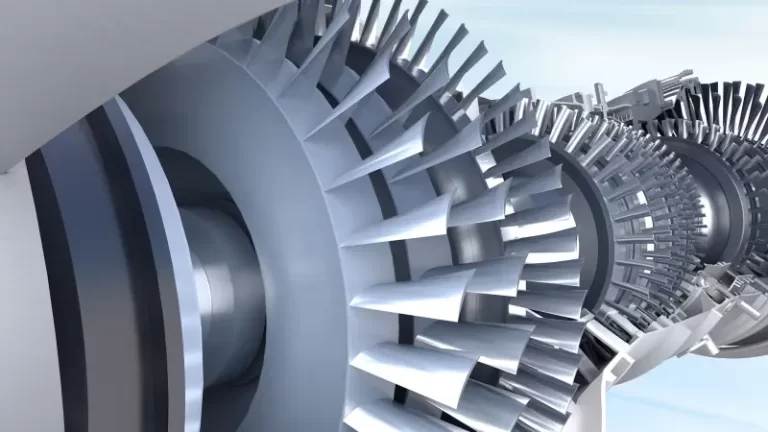

Reaction turbines are a vital component of many industrial processes, particularly in the generation of electricity. These turbines harness the power of fluid flow, converting it into mechanical energy, which is then transformed into electrical energy. Unlike impulse turbines, which operate on the principle of Newton’s third law of motion, reaction turbines function based on the Newtonian principle of action and reaction.

The Science Behind It

To understand the science behind reaction turbines, we must explore the concept of fluid dynamics. These turbines are designed to work with high-pressure fluids, such as steam or water. As the high-pressure fluid is released through nozzles, it strikes the blades of the turbine, causing them to rotate. This rotation is what generates mechanical energy.

Components of a Reaction Turbine

A reaction turbine comprises several crucial components, each playing a specific role in its operation. Let’s take a closer look at these components:

1. Rotor

- The rotor is the heart of the reaction turbine. It consists of a set of blades attached to a central shaft. When the high-pressure fluid flows over these blades, they start rotating, initiating the power generation process.

2. Nozzles

- Nozzles are responsible for directing the high-pressure fluid towards the rotor blades. Their design and placement are critical for maximizing efficiency.

3. Casing

- The casing surrounds the rotor and nozzles, creating a controlled environment for fluid flow. It prevents energy losses due to turbulence and ensures smooth operation.

4. Bearings

- Bearings support the rotor shaft, allowing it to rotate freely. Proper lubrication and maintenance are essential to prevent friction and wear.

5. Governor

- The governor regulates the flow of fluid into the turbine, ensuring it operates at a constant speed. This is crucial for maintaining a stable electrical output.

6. Generator

- The mechanical energy generated by the turbine is then transmitted to a generator, where it is transformed into electrical energy, ready to power homes and industries.

Working of Reaction Turbine

Now that we’ve covered the key components, let’s explore how a reaction turbine actually works:

1. Fluid Intake

- The process begins as high-pressure fluid, typically steam or water, enters the turbine through the nozzles.

2. Blade Interaction

- As the fluid strikes the rotor blades, it imparts a force on them. This force causes the rotor to rotate.

3. Mechanical Energy

- The rotation of the rotor generates mechanical energy, which is transferred to the generator.

4. Electrical Generation

- The generator converts the mechanical energy into electrical energy, which can then be distributed for various applications.

Parts of Reaction Turbine

Let’s delve deeper into the individual components of a reaction turbine:

Rotor

The rotor’s design is crucial for maximizing efficiency. Blades are carefully shaped to ensure optimal fluid interaction.

Nozzles

Precise design and placement of nozzles are essential to control the flow of high-pressure fluid.

Casing

The casing’s role is to maintain a controlled environment for fluid flow, preventing energy losses.

Bearings

Bearings ensure the smooth rotation of the rotor shaft and require regular maintenance.

Governor

The governor regulates fluid flow to maintain consistent turbine speed and electrical output.

Generator

The generator is where mechanical energy is transformed into electrical energy, ready for use.

Conclusion

In this in-depth exploration of “What Is Reaction Turbine? | Reaction Turbine | Working of Reaction Turbine | Parts of Reaction Turbine,” we’ve uncovered the fascinating world of these turbines, from their scientific principles to the intricacies of their components. These engineering marvels play a crucial role in generating clean and efficient energy for a wide range of applications. With their environmentally friendly characteristics and reliability, reaction turbines are at the forefront of modern power generation.

Thank you for joining us on this informative journey. If you found this article helpful, please hit the like button and consider exploring our lifetime access offers for AI-detector test and plagiarism remover tools

FAQ

How do reaction turbines differ from impulse turbines?

Reaction turbines operate on the principle of action and reaction, while impulse turbines work on Newton’s third law of motion. Reaction turbines are better suited for high-pressure fluid applications.

What industries benefit from reaction turbines?

Reaction turbines are widely used in power generation, hydroelectric plants, and various industrial processes requiring mechanical energy conversion.

Are reaction turbines environmentally friendly?

Yes, they are environmentally friendly as they can harness renewable energy sources like water and steam, reducing carbon emissions.

How do engineers optimize the efficiency of reaction turbines?

Efficiency is optimized through precise design, careful maintenance, and advanced materials to reduce energy losses.

Can reaction turbines be used for small-scale applications?

Yes, reaction turbines come in various sizes, making them suitable for both large-scale power plants and smaller applications.

Are reaction turbines reliable for continuous operation?

With proper maintenance and monitoring, reaction turbines can provide reliable and continuous power generation.