In industries where compressors and pumps are vital components of the operation, the prevention of surge is crucial to ensure the safety and efficiency of the equipment. Anti-surge controllers play a pivotal role in this regard, as they are designed to monitor and control the flow of fluids, such as gases or liquids, within a system. In this article, we will delve into the working principle of anti-surge controllers and their significance in safeguarding industrial processes.

What is an Anti-Surge Controller?

An anti-surge controller is an integral part of a control system in industries like oil and gas, petrochemical, and chemical processing. Its primary function is to prevent the occurrence of surge, a damaging and potentially catastrophic condition that can lead to equipment damage and operational downtime.

Working Principle of Anti-Surge Controllers

Anti-surge controllers operate on a sophisticated set of principles to maintain stability within the system. Here’s a breakdown of their working principle:

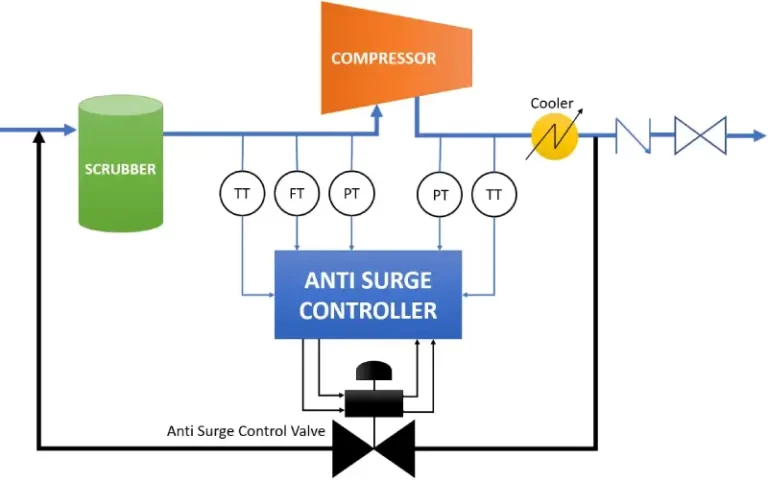

- Sensing and Measurement: Anti-surge controllers continuously monitor various parameters within the system, including flow rates, pressure, temperature, and rotational speeds of compressors or pumps. Advanced sensors provide real-time data, which is essential for precise control.

- Surge Detection: The controller utilizes algorithms and mathematical models to analyze the incoming data. It identifies any signs of impending surge, which can manifest as fluctuations in flow rates or pressure deviations.

- Control Algorithms: Anti-surge controllers employ control algorithms to make quick and accurate decisions. These algorithms consider the current system conditions, operating limits, and desired setpoints to determine the necessary corrective actions.

- Valve and Actuator Control: To counteract surge, the controller adjusts the position of control valves or dampers. These valves regulate the flow of fluids, either by partially closing or opening. By doing so, the controller ensures that the equipment operates within safe operating limits.

- Feedback Loop: Anti-surge controllers continuously gather feedback from sensors and monitoring devices. This feedback loop allows them to fine-tune their control strategies in real-time, adapting to changing conditions and preventing surge events.

- Operator Interface: In most systems, anti-surge controllers provide a user-friendly interface for operators to monitor and control the anti-surge system. Operators can set alarm thresholds, adjust control parameters, and view historical data to optimize performance.

Significance of Anti-Surge Controllers

Anti-surge controllers are vital for several reasons:

- Equipment Protection: They protect costly equipment like compressors, pumps, and pipelines from the damaging effects of surge, extending their operational lifespan.

- Safety: By preventing surge events, anti-surge controllers enhance overall safety in industrial processes, reducing the risk of accidents and potentially catastrophic failures.

- Energy Efficiency: These controllers optimize the operation of compressors and pumps, resulting in energy savings and reduced operating costs.

- Process Reliability: The consistent operation ensured by anti-surge controllers enhances process reliability, reducing unplanned shutdowns and maintenance.

- Environmental Impact: By preventing surge-induced accidents, they help prevent leaks and spills that can have adverse environmental consequences.

Conclusion

Anti-surge controllers are indispensable tools in industries reliant on compressors and pumps. Their working principle, which combines real-time data analysis, control algorithms, and precise valve adjustments, ensures the stability and safety of industrial processes. Implementing these controllers not only safeguards equipment but also promotes energy efficiency and operational reliability, making them a vital component in the modern industrial landscape.