When it comes to fluid control systems, choosing the right valve is crucial for optimal performance. In this article, we’ll delve into the distinctions between globe valves and control valves, helping you make an informed decision for your specific application.

Globe Valves: The Basics

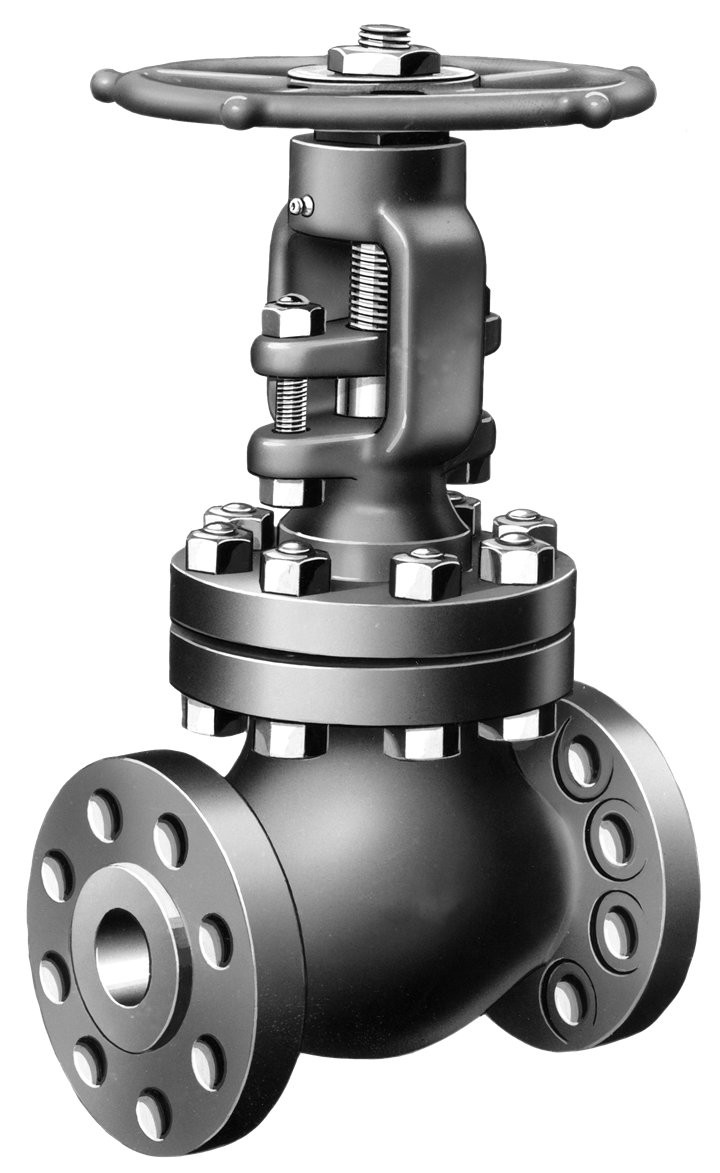

Globe valves are a fundamental component in many industrial processes. These valves are primarily designed to start, stop, and regulate the flow of a fluid within a pipeline. Here are some key characteristics of globe valves:

1. Construction

Globe valves consist of a movable disk-type element and a stationary ring seat. This design allows for precise control over flow rates. The linear motion of the disk is controlled by the valve stem.

2. Flow Regulation

One of the primary functions of globe valves is flow regulation. They excel at throttling or modulating the flow of liquids, making them suitable for applications that require fine-tuned control.

3. Application

Globe valves are commonly used in industries such as petrochemical, pharmaceutical, and manufacturing, where precise flow control is essential.

Control Valves: A Deeper Dive

Control valves, on the other hand, are a versatile option for fluid control systems. These valves go beyond simple start-stop functions and offer advanced control features:

1. Variability

Control valves provide continuous and precise control over flow rates, pressure, and temperature. They are equipped with actuators that can adjust the valve opening to maintain desired process conditions.

2. Automation

Control valves are often integrated into automated systems, allowing for remote operation and adjustments. This level of automation enhances efficiency and reduces the need for constant manual monitoring.

3. Application

Control valves find extensive use in industries like power generation, water treatment, and HVAC systems, where automated control and accuracy are paramount.

Key Differences

Now that we’ve explored the fundamental characteristics of both globe valves and control valves, let’s highlight the key differences between them:

1. Functionality

- Globe valves are primarily designed for on/off and throttling applications.

- Control valves offer precise control and automation capabilities.

2. Flow Control

- Globe valves provide moderate control over flow rates.

- Control valves offer precise control over flow, pressure, and temperature.

3. Applications

- Globe valves are commonly used in processes where simple regulation is sufficient.

- Control valves are ideal for systems that require automated and accurate control.

In conclusion, the choice between a globe valve and a control valve depends on the specific needs of your application. If you require basic flow regulation, a globe valve may suffice. However, for processes demanding advanced control, automation, and accuracy, a control valve is the superior choice.

Make an informed decision based on your unique requirements, and ensure that your fluid control system operates at its best efficiency.

We hope this article has been useful to you. Mehragan Petro Pars company provides this product and similar products with the highest quality to customers