In industrial settings where combustion processes are integral, the safety and efficiency of burner operations play a crucial role. Burner Management System (BMS) is sophisticated control system that ensures the safe startup, operation, and shutdowns of burners. This article explores the various aspects of BMSs, their components, design considerations, installation, testing, and maintenance procedures, as well as regulatory standards and future trends.

Understanding BMSs

Burner Management Systems (BMS) are designed to supervise and control the operation of burners, which are commonly used in industrial processes such as power generation, oil and gas refining, chemical manufacturing, and more. The primary function of a BMS is to provide a safe and reliable means of igniting and controlling the combustion process while ensuring the protection of personnel, equipment, and the environment.

Components of a Burner Management System

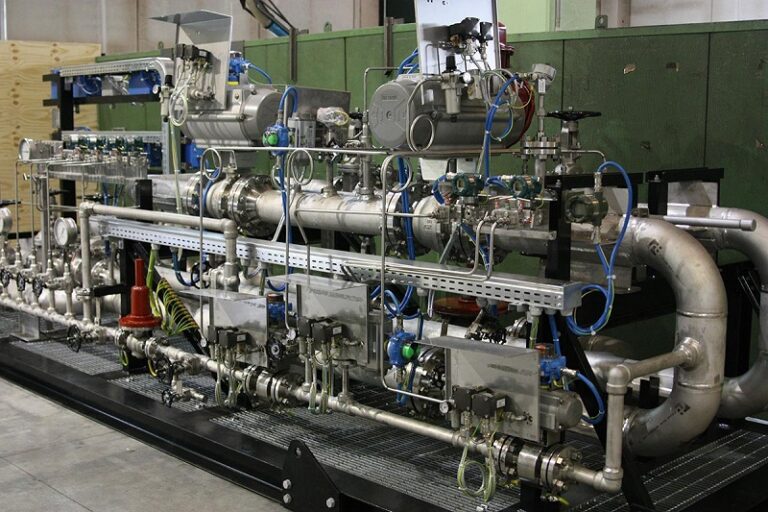

A typical BMS consists of several key components:

Flame Safeguard System

The flame safeguard system is responsible for monitoring and controlling the burner’s flame. It utilizes sensors to detect the presence and stability of the flame, ensuring that it remains within safe limits and automatically shutting down the burner if any abnormalities are detected.

Combustion Control System

The combustion control system regulates the fuel and air supply to maintain optimal combustion conditions. It continuously monitors and adjusts parameters such as fuel flow, air-to-fuel ratio, and flame stability to achieve efficient and environmentally friendly burner operation.

Safety Shutdown System

The safety shutdown system is an essential part of the BMS, providing emergency shutdown capabilities in critical situations. It monitors various parameters such as high pressure, high temperature, flame failure, and other abnormal conditions, triggering immediate shutdown actions to prevent accidents and equipment damage.

Burner Management Panel

The burner management panel serves as the central control unit for the entire BMS. It receives signals from the flame safeguard system, combustion control system, and safety shutdown system, coordinating their actions and providing necessary inputs for safe and efficient burner operation.

The Importance

Burner Management Systems are crucial for ensuring safe and efficient burner operations in industrial processes. Here are some key reasons why BMS is essential:

Safety Assurance

The primary purpose of a BMS is to ensure the safety of personnel, equipment, and the surrounding environment. By continuously monitoring the burner’s operation, detecting abnormal conditions, and initiating shutdown actions when necessary, BMS prevents accidents, fires, and explosions, minimizing the risk of injury and property damage.

Compliance with Regulations

Industrial processes involving burners are subject to strict regulatory standards to maintain safety and environmental compliance. A properly designed and implemented BMS helps organizations meet these standards and avoid penalties, legal liabilities, and reputational damage.

Enhanced Operational Efficiency

Efficient combustion directly impacts operational costs and energy consumption. Burner Management Systems optimize fuel-air mixture, combustion stability, and other parameters, leading to improved efficiency, reduced emissions, and lower operating costs.

Design Considerations for Burner Management Systems

When designing a Burner Management System, several factors must be considered to ensure its effectiveness and reliability:

System Redundancy

Redundancy is crucial for critical control systems like BMS. Implementing redundant components, such as flame sensors, control valves, and shutdown relays, increases system reliability and provides fail-safe mechanisms.

Hazard Analysis

A comprehensive hazard analysis should be conducted to identify potential risks associated with burner operations. This analysis helps in designing appropriate safety measures and specifying the required functionality of the BMS.

Interoperability and Integration

Integration with other control systems, such as Distributed Control Systems (DCS), is vital for seamless operation and data exchange. BMS should be designed to communicate and coordinate with these systems effectively.

Installation and Configuration of Burner Management Systems

The proper installation and configuration of a Burner Management System are critical to its performance. Trained professionals should follow manufacturer guidelines and industry best practices to ensure correct wiring, sensor placement, parameter settings, and interlock connections.

Testing and Maintenance of Burner Management Systems

Regular testing and maintenance are essential to keep the BMS in optimal condition. Functional tests, periodic inspections, and calibration of sensors and control devices should be conducted as per manufacturer recommendations and regulatory requirements.

Common Challenges and Troubleshooting

Despite their importance, Burner Management Systems can encounter challenges. Common issues include flame instability, false alarms, sensor failures, and communication problems. Troubleshooting techniques should be employed to identify and resolve these issues promptly.

Regulatory Standards and Compliance

Burner Management Systems must comply with various regulatory standards, such as the National Fire Protection Association (NFPA) guidelines, the International Electrotechnical Commission (IEC) standards, and local safety regulations. Organizations must stay updated with the latest standards to ensure compliance and avoid legal consequences.

Advancements in Burner Management Systems

With technological advancements, BMSs have evolved to offer enhanced safety, efficiency, and connectivity. Integration with Industrial Internet of Things (IIoT) platforms, advanced analytics, remote monitoring capabilities, and predictive maintenance are some notable advancements in BMS technology.

Future Trends in BMSs

The future of Burner Management Systems holds exciting possibilities. Machine learning algorithms, artificial intelligence, and advanced sensor technologies are likely to play significant roles in improving safety, efficiency, and automation in burner operations. The focus will also be on developing more intuitive user interfaces and cloud-based management systems.

Conclusion

In summary, Burner Management Systems are vital for ensuring safe and efficient burner operations in industrial processes. By integrating flame safeguard systems, combustion control systems, safety shutdown systems, and burner management panels, organizations can achieve optimal performance, compliance with regulations, and enhanced operational efficiency.